Consumer demand for green packaging is providing a tailwind for eco and recycled materials but more policy support and collaboration is needed before the industry can make a bigger decarbonization impact, according to executives at Nomura Greentech’s Sustainable Leaders Summit.

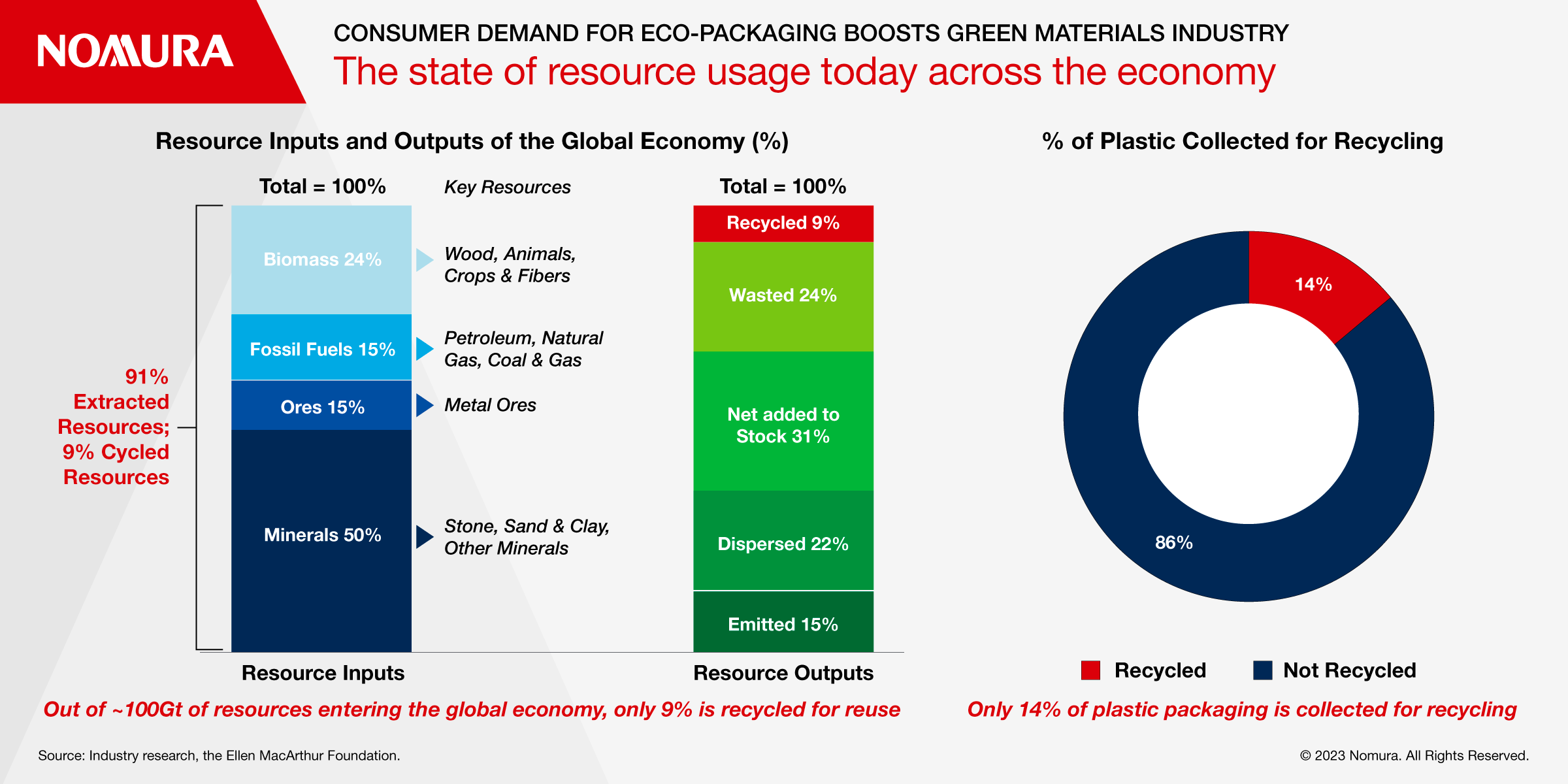

The market for green materials and packaging holds untapped potential given the right incentives as recycling today captures only 9% of natural resources and 14% of plastic.

Plastics recycling faces particular difficulties as it requires substantial energy for sorting and separation processes to achieve the purity needed for chemical recycling, according to an executive who spent 25 years in the chemicals industry and spoke at the summit, held under the Chatham House Rule.

Cost is also an issue as recycled materials are often more expensive than virgin inputs. The chemicals executive is at a company that takes discarded waste plastic that can’t be recycled and turns it back into hydrocarbons using a proprietary technology.

“A tremendous amount of energy sitting in the ground or being incinerated today can actually be reused and become renewable.”

Other challenges include sorting the materials due to a lack of infrastructure to collect and aggregate waste plastics at scale.

A recycling executive explained that US municipalities create different grades of bale and sell them into the recycling market. A polyethylene (PET) bale may have a 20% yield or an 80% yield depending on how well it has been separated.

He said that buying a B-grade bale makes the recycling process uncompetitive as so much time and expense goes into further separation; to increase recycling rates, he said it would be better to limit packaging to 3 materials: polypropylene, high density and PET.

A big driver of the green materials industry is now coming from major brands and customers, according to two manufacturers who noted that consumers are willing to pay a ‘green premium’ for renewable products especially on visible goods like packaging.

A Europe-based executive whose company is constructing an eco-plastics plant said that his product costs 4 times as much as PET yet it’s already sold out and the factory hasn’t even started production.

The importance of collaboration across the value chain was emphasized for example with consumer brands and chemical companies partnering to develop recyclable packaging.

The executives also discussed how to scale the industry and concluded that greater project finance and policy incentives are necessary to construct more advanced recycling facilities in a similar vein to the early days of renewables, noting that heavily subsidized state and federal policies enabled solar and wind. They said that the U.S. Inflation Reduction Act offers renewables incentives but lacks support for recycling.

A green materials investor spoke about the importance of finding businesses that are backed by policy tailwinds, noting that “we think about commodities cyclicality but there is a policy cyclicality too.” He said that often the use case for a new product doesn’t just depend on one policy but the combination of four or five subsidy-seeking strategies grouped together - the policies may have different expiration dates or different regulatory overhangs but when they come together, they provide great opportunities.

The CEO of a venture capital firm explained that she has a dedicated pot of capital to allocate towards very early stage investments that includes investing in a mushroom bacon company that is also involved in mushroom leather and mushroom-based packaging that would eventually go back into the ground.

Several executives highlighted the promise of biology and biotech, using enzymes to create renewable materials from organic feedstock like plant sugars while noting challenges including scaling-up and ensuring consistent product performance.